Air conditioners use a closed-loop refrigeration system. Under normal operating conditions, the refrigerant (commonly referred to as “Freon” or “coolant”) does not get used up or deplete over time like fuel or oil.

If your system frequently runs low on refrigerant, it’s a strong indication that a leak exists somewhere in the system.

Common leak locations include:

– Corroded or punctured indoor evaporator coil

– Loose or aged copper line connections

– Leaking service valves or compressor seals

Simply refilling the system without locating and repairing the source of the leak is only a temporary fix—it does not resolve the underlying issue.

Key Point: Adding refrigerant is not a maintenance routine. It is an emergency response to a fault condition and requires further technical investigation.

While refilling refrigerant may restore cooling performance for a short time, the long-term impact on efficiency, cost, and equipment lifespan can be significant.

Why repeated charging is problematic:

– The system will often operate under improper pressure, straining the compressor and control board

– Cooling efficiency decreases, causing the unit to run longer and consume more electricity

– Operating costs increase significantly over time

– Persistent leaks can damage major components, such as the compressor or fan motor

Rather than treating symptoms, it’s more effective to identify whether the system can be reliably repaired—or if replacement is more cost-efficient over time.

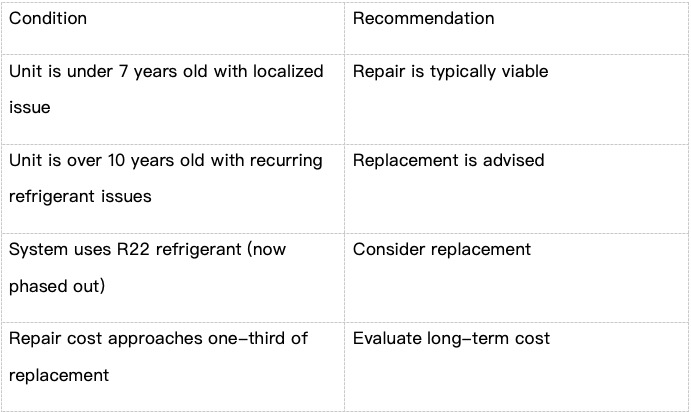

The decision between repairing an existing system or investing in a new one depends on several factors: age, efficiency, refrigerant type, and total repair cost.

Please see general reference below.

In technical assessments, it’s best to consider:

– Current system health and structural condition

– Projected future use (years remaining)

– Energy efficiency performance under load

Even if the system appears to operate, aging components such as coils, valves, and sensors can reduce thermal transfer and control response over time. Leaks worsen this degradation.

Common performance issues in aging units:

– Slower cooling and longer runtime

– Inconsistent temperature regulation across rooms

– Higher operating noise levels

– Elevated utility bills even with moderate use

For units that still rely on R22 refrigerant, which is no longer manufactured or imported due to environmental regulations, even basic maintenance becomes increasingly difficult or non-compliant.

Air conditioners are not designed to be endlessly patched. Frequent refrigerant charging is a strong indicator that the system is no longer sealed or efficient—and may be approaching end-of-life.

Professional attention is advised if:

– Refrigerant has been added more than once in a season

– Cooling output remains poor even after service

– Compressor noise and pressure readings fluctuate

– System uses obsolete or phased-out refrigerants

– Electricity consumption has noticeably increased

Instead of recurring temporary fixes, a thorough technical evaluation will help determine whether your existing system can be reliably repaired—or whether a full system upgrade is warranted from both an engineering and energy-efficiency standpoint.

For more information on HVAC system troubleshooting, maintenance best practices, and equipment lifecycle planning, consult a licensed HVAC technician or refer to additional technical resources on our website.

GTA Leading provider of heating, cooling, and water heating and treatment needs for over 15 years.

Get 5% off when you sign up for emails with savings and tips.

© 2024 ICARE HOME COMFORT INC. Design by Tensor Canada | Privacy Policy | Terms and Conditions